Chinese Professional Magnesia-Hercynite - Rotary kiln – BBMG

Chinese Professional Magnesia-Hercynite - Rotary kiln – BBMG Detail:

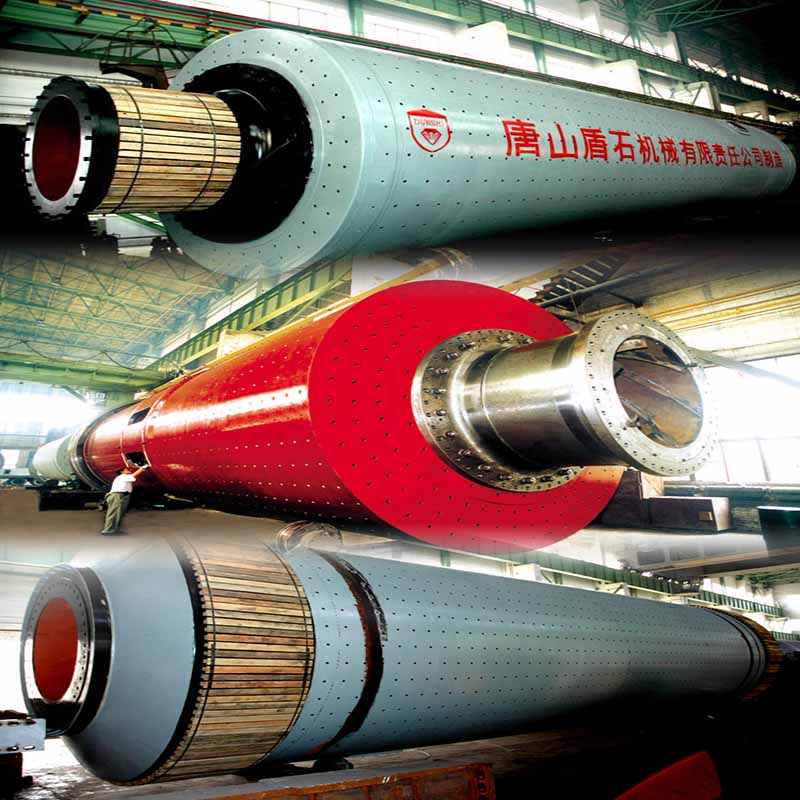

The shell of rotary kiln is made of steel plate, the interior of the kiln shell is lined with refractory, there is a specified angle between the shell and the horizontal line,and the shell is supported by 3 tyres with each retaining supporting device. A big girth gear is fixed on the kiln feed inlet tyre by a tangential spring plate ,and a pinion meshes with it below.In normal operation, the main drive motor transmits power to the open gear device through the main reducer to drive the rotary kiln.

The materials are fed and burned inside the kiln through the kiln inlet( the higher end of the shell). Due to the kiln tilt and slow rotation of the kiln, the materials rolls along the circular direction and moves along the axial direction (from the higher end to the lower end), continuing to process of decomposition and burning. In the end, the clinker is produced and passes through the kiln outlet hood and cooled inside the clinker cooler.

|

PRODUCT NAME |

SPECIFICATION |

OUTPUT(T/D) |

SPEED (r/m) |

NUMBER OF SUPPORT |

REDUCER |

MOTOR |

||

|

|

|

|

|

|

TYPE |

NOMINAL SPEED RATIO |

TYPE |

POWER |

|

ROTARY KILN |

∅4×60M |

2500 |

0.41-4.1 |

3 |

ZSY630-31.5-Ⅴ |

31.5 |

ZSN4-355-092 |

315 |

|

ROTARY KILN |

∅4×60M |

2500 |

0.396-3.96 |

3 |

ZSY630-35.5-Ⅰ |

35.5 |

ZSN4-355-092 |

315 |

|

ROTARY KILN |

∅4.3×60M |

3200 |

0.43-4.3 |

3 |

YNS1400-28VIDL |

28 |

ZSN4-355-12 |

420 |

|

ROTARY KILN |

∅4.3×64M |

3000 |

VFD,MAX.4 |

3 |

H3SH19-28 |

28 |

YPT500-8 |

450 |

|

ROTARY KILN |

∅4.3×66M |

3200 |

0.4-4.3 |

3 |

ZSY710-35.5-Ⅱ | 31.5 | ZSN4-355-12 | 420 |

|

ROTARY KILN |

∅4.8×72M |

5000 |

0.447-4.47 |

3 |

YNS1760-28VDR |

28 |

ZSN4-450-092 | 710 |

|

ROTARY KILN |

∅4.8×72M |

5000 |

0.396-3.96 |

3 |

JH800C-SW306-31.5 |

31.5 |

ZSN4-400-22 |

630 |

Product detail pictures:

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for Chinese Professional Magnesia-Hercynite - Rotary kiln – BBMG , The product will supply to all over the world, such as: Finland, Doha, Montreal, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!