Short Lead Time for Limestone Grinding Mill - Slag vertical mill – BBMG

Short Lead Time for Limestone Grinding Mill - Slag vertical mill – BBMG Detail:

Slag vertical mill is a negative pressure air sweeping type grinding equipment, which will dry the slag and grind the slag.

The slag ground by the grinding roller on the grinding disc is composed of two parts: a small part of new slag with high water content and most of the ground non-finished slag with lower water content. This part of non-finished slag is the coarse material returned after separation by the separator because of the larger particles. The strong negative pressure wind caused two parts of slag to fall onto the grinding disc.

Under the action of centrifugal force, the slag is guided to the auxiliary grinding roller, and the slag is compacted by reducing the blowing of the auxiliary grinding roller. The auxiliary grinding roller keeps a certain distance from the grinding disc, and is fixed on the rocker arm with very light weight.

The main grinding roller is fixed on the thicker main rocker arm, and the configured material layer is ground by pressure grinding. The force is generated by the weight of the grinding roller itself and the pressure of the hydraulic system.

The grinding roller rotates by rubbing against the abrasive bed. The sensor and buffer limit device installed on the rocker arm can prevent direct metal contact between the grinding roller and the grinding disc.

The ground slag particles are thrown out by the centrifugal force and flow through the retaining ring. Here it is captured by the airflow rising through the wind ring, and the dust and gas flow through the grinding chamber, so that it is surrounded by the vertical grinding cylinder equipped with wear-resistant lining and enters the powder separator. The powder separator is installed or welded on the vertical mill barrel.

Without the help of auxiliary transmission, the vertical mill can be directly loaded and started by the main motor under the condition of loading (after a short shutdown). In order to unload the main motor, the grinding roller is hydraulically lifted to reduce the pressure of the hydraulic system. The oil can be introduced into the rodless cavity of the hydraulic cylinder.

|

SPECIFICATION |

NOMINAL CAPACITY |

GRINDING DISC DIAMETER |

MAXIMUM FEED SIZE |

REDUCER |

MOTOR |

||

|

TYPE |

SPEED RATIO |

TYPE |

POWER |

||||

| Slag Vertical Mill | |||||||

| φ4.6 | 90 | 4600 | 0~90 | JLP330 | 37.7328 | YRKK800-6 | 3000 |

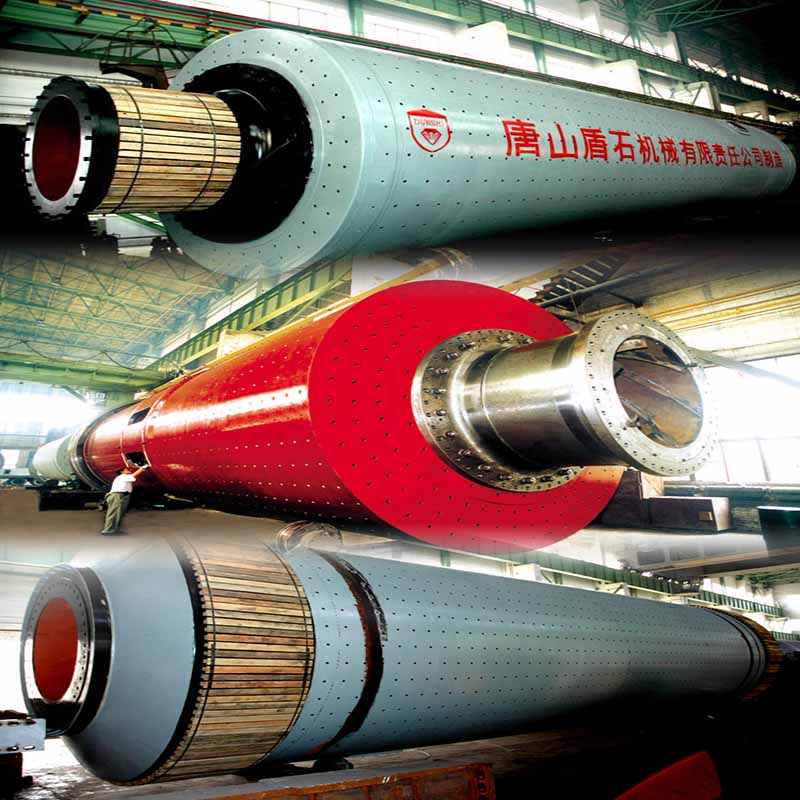

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Short Lead Time for Limestone Grinding Mill - Slag vertical mill – BBMG , The product will supply to all over the world, such as: Croatia, Chicago, Swaziland, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!